-

Professional Technology

-

About Sunflex

- Investors

-

Join us

Professional Technology

About Sunflex

About Sunflex

Smart Factory

Smart Factory Tour

Start

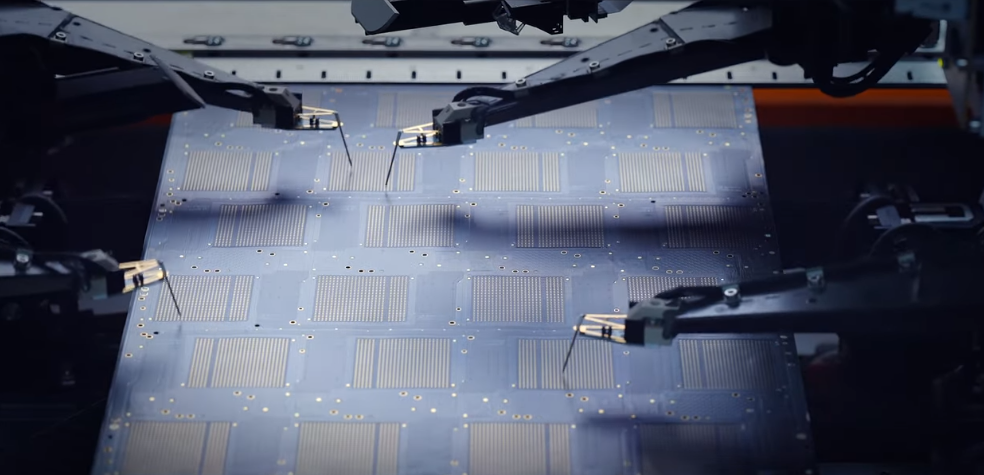

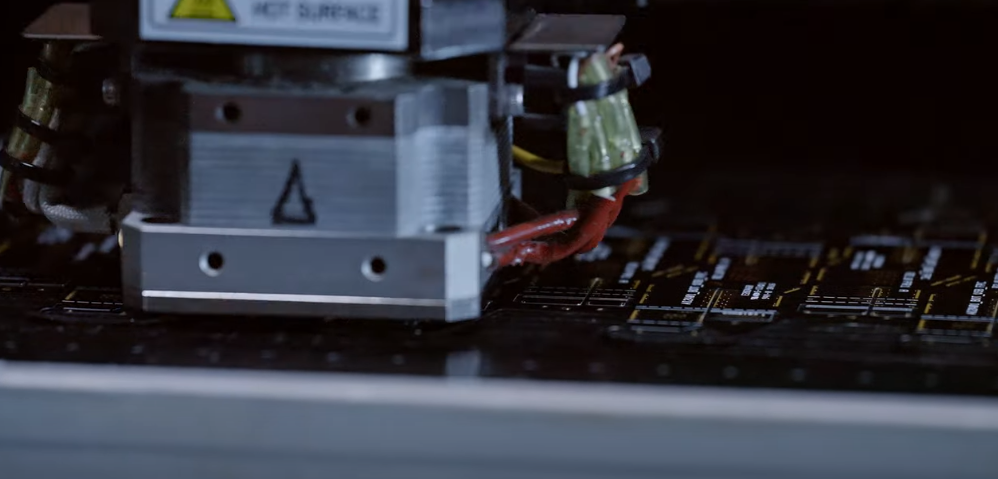

Flying Probe Test

Flying probe testing is a technique used for inspecting printed circuit boards (PCBs). It utilizes movable probes to check electrical connectivity and functionality across the board. As it eliminates the need for custom test fixtures, this method is ideal for prototype validation and low-volume production.

01

Pico-second Laser Cutting

Picosecond laser cutting is a high-precision technique that utilizes ultra-short laser pulses in the picosecond range. It produces an extremely small heat-affected zone and minimizes carbonization, making it suitable for processing miniature parts and materials requiring exceptional cutting accuracy.

02

.png)

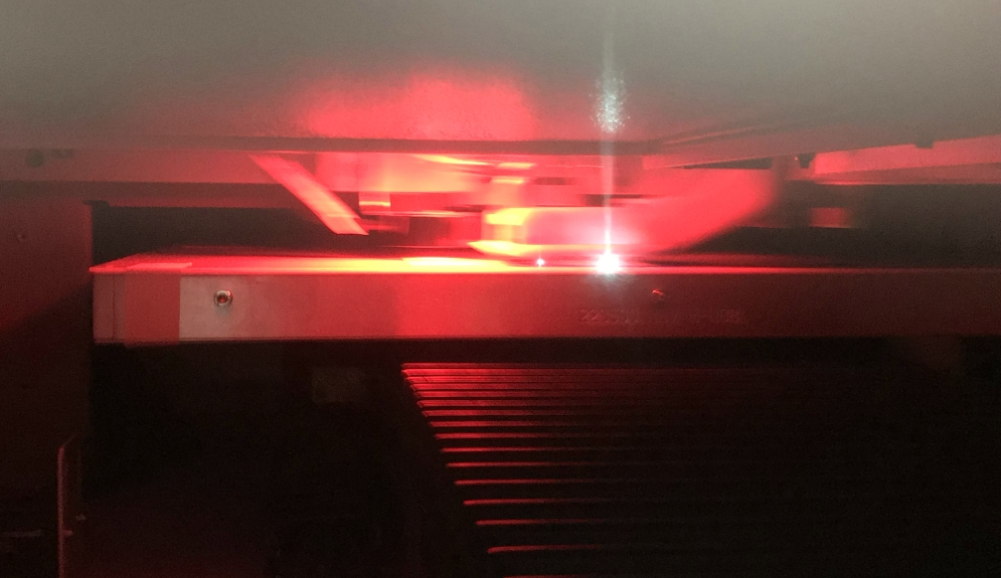

Laser Drilling

UV laser drilling is a technique for creating fine, precise holes in materials, often used for micro-hole fabrication. It is particularly suitable for non-rigid substrates and for drilling through-holes or blind vias with ultra-small diameters, offering precision beyond the capabilities of traditional mechanical drilling

03

Solder Mask Laser Direct Imagaing

Laser exposure for solder mask application on FPCs involves precisely directing a laser beam onto the surface to pattern the solder mask layer. This process accurately transfers the solder mask film to targeted regions, effectively preventing solder from adhering where it is not needed during assembly.

04

Automated Optical Inspection

AOI employs optical systems to automatically identify circuit defects in the FPC production process, helping to enhance manufacturing yield and quality

05

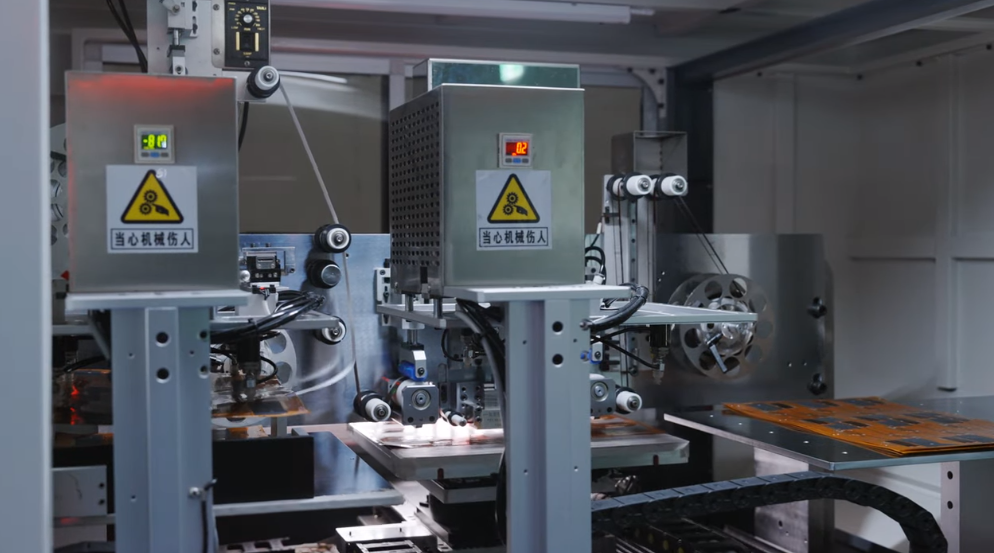

Direct Punch and Paste Reinforcement Machine

This reinforcement method in FPC production involves direct punching technology to bond materials precisely, reinforcing targeted sections of the FPC. This approach increases bonding efficiency and ensures higher quality and dimensional accuracy.

06

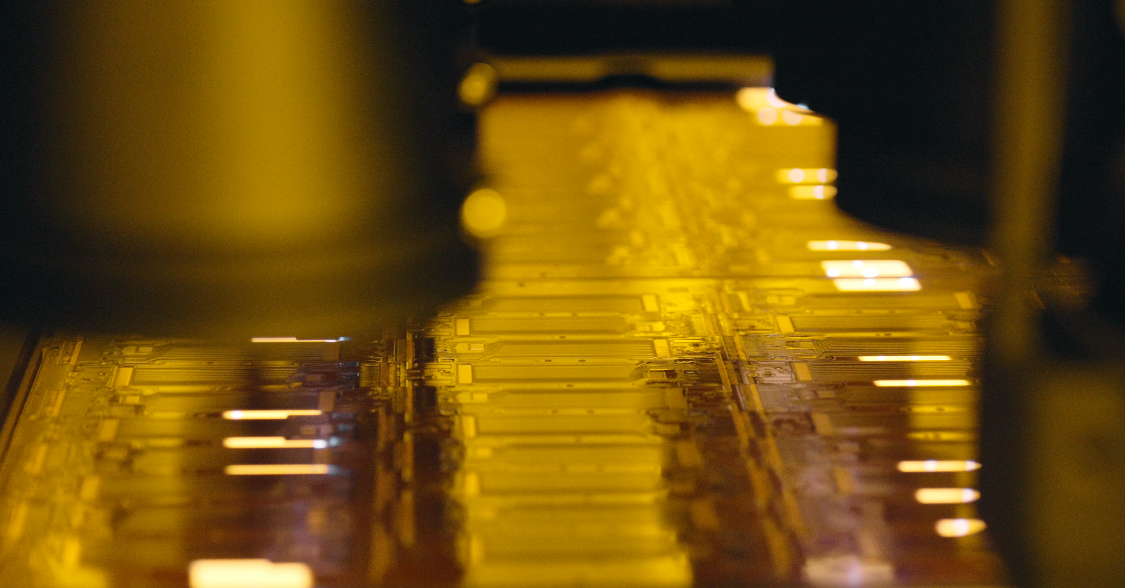

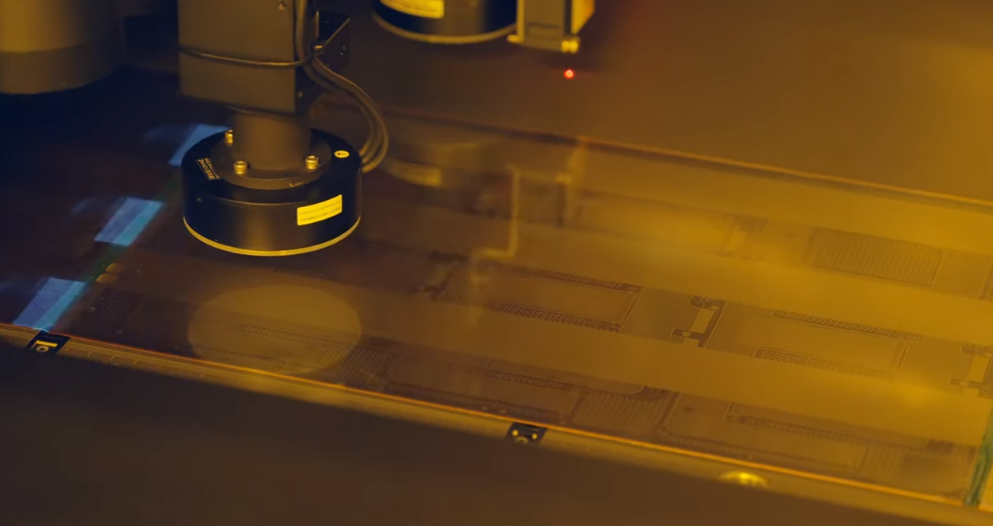

RTR Laser Direct Imaging

Circuit laser exposure technology is widely applied in FPC manufacturing, utilizing laser light to accurately transfer circuit patterns onto the substrate. Its exceptional precision makes it well-suited for fabricating fine and detailed circuitry

07

Automatic Steel Stifferener Pasting

This automated lamination technology bonds steel sheets with other materials, typically applied to produce reinforcement plates or to integrate steel components that strengthen structural integrity. It enhances bonding efficiency and delivers precise, high-quality results.

08